We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

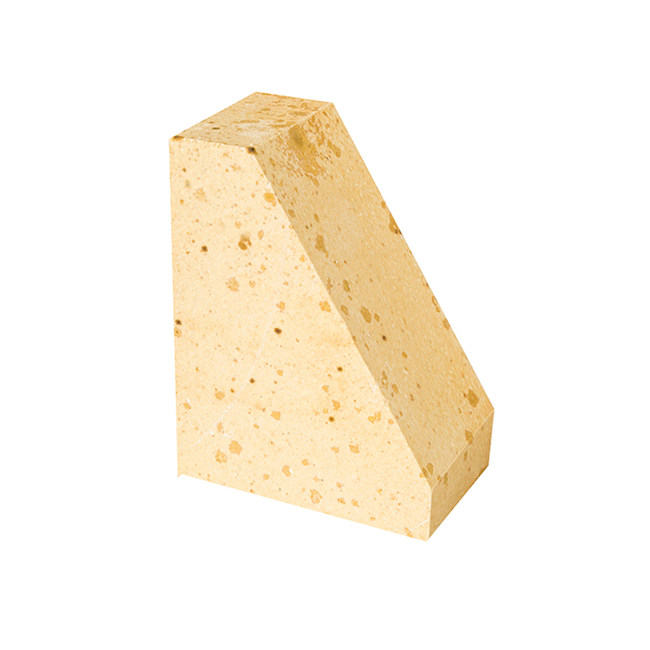

Product description of silicon brick

Silica brick is a kind of acid refractory, which is mainly composed of scaly quartz, cristobalite and a small amount of residual quartz and glass phase. It has good resistance to acid slag corrosion, the softening temperature of filler can reach 1640~1670 ℃, and the volume is relatively stable for long-term high-temperature use.

Details of silicon brick

Silica brick has the characteristics of high purity, high strength, wear resistance and high density, as well as high thermal shock resistance, volume stability and low creep performance. It is widely used in glass smelting furnace, coke oven, hot blast furnace and other high-temperature thermal equipment. In particular, high-temperature thermal equipment can be repaired at will without ceasing fire.

More relevant refractory products: Acid resistant castable

Parameters of Silica bricks

| Silica bricks for coke oven | Furnace bottom, furnace wall | Other |

| SiO2 % ≥ | 94.5 | 94 |

| Al2O3 % ≤ | 1.2 | 1.5 |

| Fe2O3 % ≤ | 1.2 | 1.5 |

| CaO % ≤ | 3.0 | 3.0 |

| Na2O+K2O % ≤ | 0.35 | 0.35 |

| Apparent porosity % ≤ | 22 | 24 |

| Normal temperature compressive strength MPa ≥ | 35 | 28 |

| 0.2MPa Load softening temperature℃ ≥ | 1650 | |

| True Density g/cm3 ≥ | 2.33 | 2.34 |

| Reburn line change % 1450℃x2h | 0-0.2 | |

| Coefficient of thermal expansion 1000℃ % ≤ | 1.28 | 1.3 |