We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

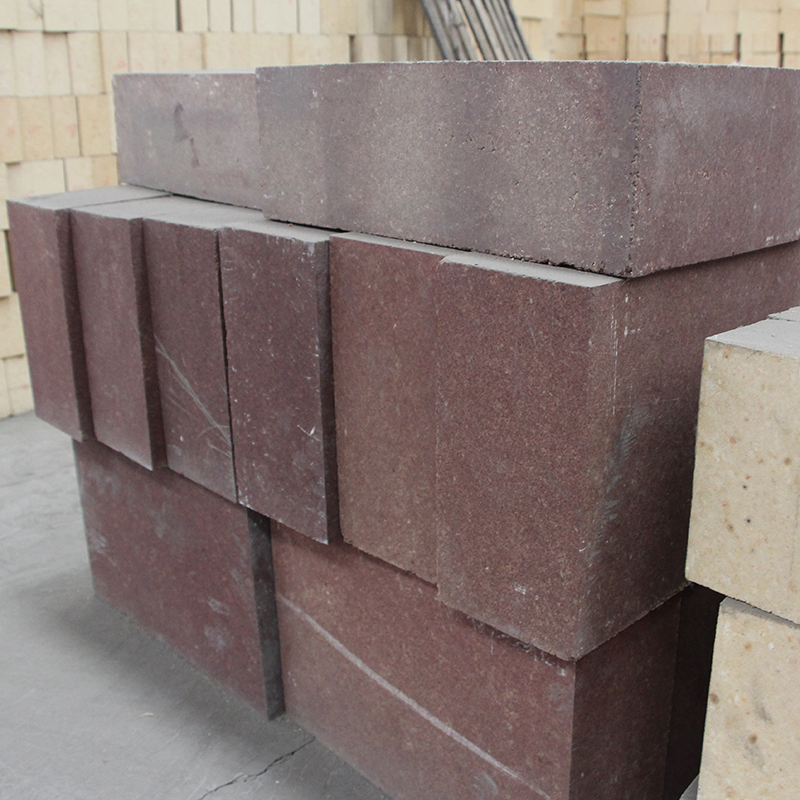

Product introduction of magnesia chrome bricks

Ordinary magnesia chrome brick is made of sintered magnesia and chromium-magnesia ore. This kind of brick has high refractoriness, high temperature strength, strong resistance to alkaline slag erosion, excellent thermal stability, and certain adaptability to acid slag.

Features of magnesia chrome bricks

Spalling

Good thermal stability

Strong erosion resistance to alkaline slag

Magnesia chrome bricks have high fire resistance

Application of magnesia chrome bricks

Magnesia chrome brick is mainly used in cement rotary kiln, glass kiln regenerator chamber, steel furnace lining, refining ladle permanent layer, non-ferrous metallurgy furnace, lime kiln, iron mixing furnace and refractory high temperature furnace lining, etc. The high temperature parts of the wall of the ultra-high power electric furnace are made of fused magnesia chrome bricks, the high erosion area of the refining furnace outside the furnace is made of magnesia chrome bricks made of synthetic materials, and the high erosion area of the non-ferrous flash melting furnace is made of fused magnesia chrome bricks and synthetic materials.

Parameters of magnesia chrome bricks

| Model | MGe6 | MGe8 | MGe12 | MGe16 | DMGe4 | DMGe8 | DMGe12 | DMGe16 |

| MgO % | 80 | 72 | 70 | 65 | 85 | 77 | 74 | 69 |

| Cr2O3 % | 7 | 10 | 13 | 17 | 5.5 | 9.1 | 14 | 18 |

| CaO % | 1.2 | 1.2 | 1.2 | 1.2 | 1.1 | 1.4 | 1.2 | 1.2 |

| SiO2 % | 3.4 | 4 | 4 | 4.2 | 1.3 | 1.2 | 1.2 | 1.5 |

| Al2O3 % | 4.5 | 6.5 | 6 | 6 | 3.5 | 4 | 3.5 | 4.5 |

| Fe2O3 % | 4 | 4.8 | 5.5 | 6.5 | 3 | 6.4 | 5 | 5.7 |

| Apparent Porosity % | 17 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Bulk Density g/cm3 | 3 | 3 | 3.02 | 3.05 | 3.02 | 3.04 | 3.06 | 3.08 |

| Cold Crushing Strength Mpa | 55 | 55 | 55 | 50 | 50 | 50 | 55 | 55 |

| Refractoriness Under Load °C | 1600 | 1600 | 1600 | 1600 | 1700 | 1700 | 1700 | 1700 |

| Thermal expansion % 1000°C | / | / | / | / | 1 | 1 | 1 | 0.9 |

| Thermal expansion % 1600°C | / | / | / | / | 1.8 | 1.8 | 1.8 | 1.6 |