We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

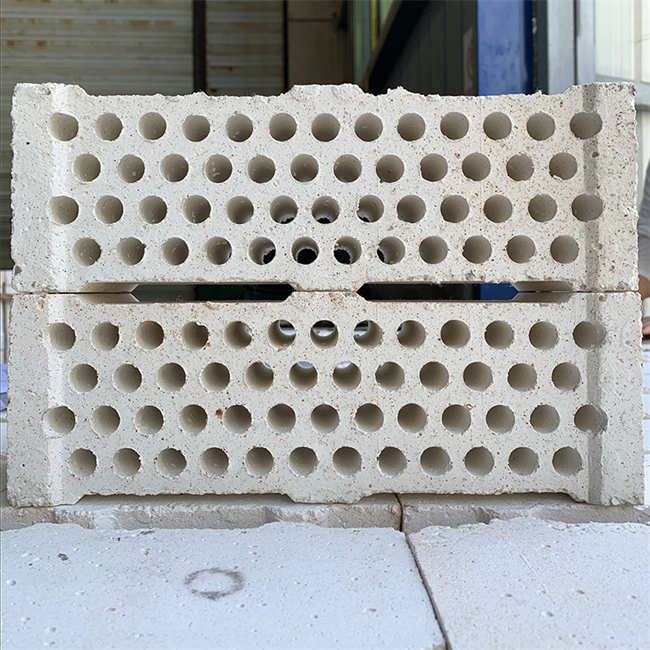

Product description of honeycomb ceramic regenerator

The surface of honeycomb ceramic regenerator is mainly composed of square and hexagonal pore structures, and the pores are parallel to each other. This structure greatly reduces the resistance of the air hole passing through, and greatly improves the heat transfer efficiency of the single hole volume of the regenerator.

Features of honeycomb ceramic regenerator

Honeycomb ceramic regenerator has the characteristics of low thermal expansion, large specific heat capacity, large specific surface area, small pressure drop, small thermal resistance, good thermal conductivity, and good thermal shock resistance.

More relevant refractory products: Cement CA70

Parameters of honeycomb ceramic regenerator

| Material | Loose Cordierite | Dense Cordierite | Cordierite Mullite | Mullite | Corundum Mullite |

| Al2O3, % | 33-35 | 35-37 | 33-35 | 59-61 | 69-72 |

| SiO2, % | 48-50 | 48-50 | 48-51 | 37-39 | 28-30 |

| Thermal Expansion (Room Temp.-1000%)×10-6/℃ | 1.5-1.8 | 2-2.5 | 2.0-3.0 | 4.2-5.0 | 4.5-5.2 |

| Thermal Capacity(Room Temp.-1000℃), J/kg | 750-900 | 800-1200 | 1100-1300 | 1100-1300 | 1300-1400 |

| Heat Shock Resistance ℃ | 300 | 250 | 300 | 230 | 260 |

| Softening Temperature℃ | 1280 | 1350 | 1400 | 1630 | 1680 |

| Refractoriness ℃ | 1360 | 1410 | 1480 | 1750 | 1790 |

| Max Service Temperature | 1200 | 1300 | 1350 | >1550 | >1600 |