We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

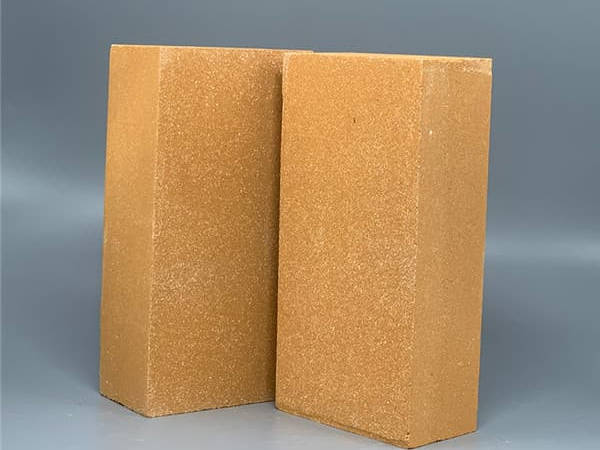

Brief introduction of fire clay insulation bricks

Light weight fire clay insulation brick is a kind of high temperature heat insulation refractory material, it takes refractory clay clinker as raw material, to plastic clay as binder, add the right amount of combustible or foaming agent, through the brick press molding, and then sintering. Lightweight clay insulation brick is generally used as insulation layer of high temperature kiln, as heat insulation material.

Features of fire clay insulation brick

Light weight fire clay insulation brick with its high porosity, low volume density, good heat insulation performance, is widely used in all kinds of industrial kiln inside the fire brick and ketone body between the space of heat insulation filling material, to reduce the kiln heat loss so as to obtain high energy utilization efficiency.

More relevant refractory products: Cement CA80S

Parameters of fire clay insulation brick

| Index | QN-0.6 | QN-0.8 | QN-1.0 |

| Bulk & Density (g/cm3) ≥ | 0.6 | 0.8 | 1 |

| Cold Crushing Strength (MPa) ≥ | 2 | 3 | 4 |

| Heat Conductivity (900℃±25) (W/m·k) ≤ | 0.25 | 0.3 | 0.5 |