We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

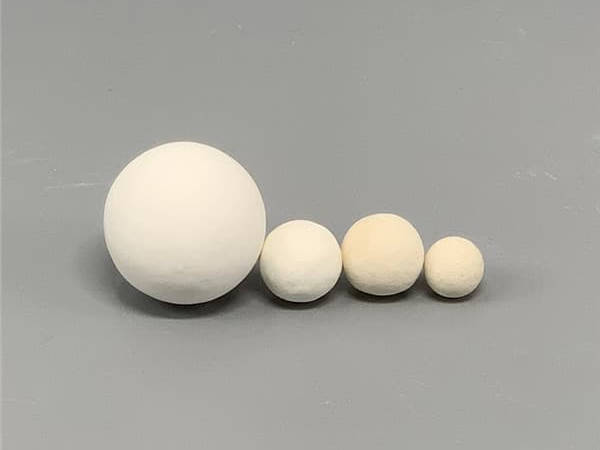

Product introduction of high aluminum refractory ball

The high aluminum refractory balls are very strong in chemical strength, long period of use, chemical stability, and good heat resistance, and are suitable for facilities such as urea, iron and other industrial wind blowers and heating converters.

Features of high aluminum refractory ball

- High mechanical strength and long use

- Chemical stability

- The best heat resistance of refractory porcelain ball can reach

Parameters of high alumina refractory ball

| Item | High alumina | Low creep | Mullite | Corundum |

| Size(mm) | 40-80 | 40-80 | 40-80 | 40-80 |

| Al2O3(%) | 65 | 70 | 75 | 95 |

| Refractoriness under load(°C) | 1450 | 1460 | 1530 | 1650 |

| Apparent Porosity(%) | 25 | 23 | 22 | 18 |

| Bulk Density(g/cm3) | 2.3 | 2.4 | 2.5 | 3.1 |

| Cold crushing strength(Mpa) | 13 | 14 | 32 | 36 |

| Thermal shock resistance (1100°Cwater cooling) cycle ≥ | 15 | 10 | 20 | 7 |

| Refractoriness(°C) | 1710 | 1750 | 1800 | 1800 |

Applications of high aluminum refractory ball

The high aluminum refractory ball is suitable for the heat storage sphere combustion system of the gas and non gas fuel industrial furnace, and it is suitable for the heat storage type heating furnace of the steel industry, the heat storage type steel packaging baking equipment, the air separation equipment heat storage equipment in the space division industry, and the heat storage type melting furnace of the nonferrous metal industry. It can also be used as a heat storage carrier for a large scale forging plant, a heat storage type electric boiler, and a heat storage type incinerator.