We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

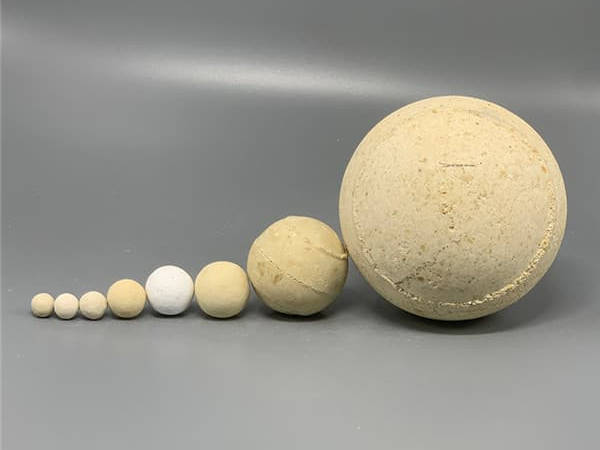

Product introduction of high aluminum refractory ball

The high alumina refractory ball is made of industrial alumina and refractory kaolin as the main materials. It is scientifically formulated, shaped and calcined at high temperature.

Details of high aluminum refractory ball

The production process of high alumina fireball is similar to that of refractory brick, which shall be determined according to material characteristics, requirements for high alumina fireball, production conditions and other factors. Strict grading of raw materials, graded storage of particles, iron removal, and combined fine grinding of some clinker and clay are of great significance for improving and stabilizing the quality of high alumina fireballs.

Parameters of high alumina refractory ball

| Item | High alumina | Low creep | Mullite | Corundum |

| Size(mm) | 40-80 | 40-80 | 40-80 | 40-80 |

| Al2O3(%) | 65 | 70 | 75 | 95 |

| Refractoriness under load(°C) | 1450 | 1460 | 1530 | 1650 |

| Apparent Porosity(%) | 25 | 23 | 22 | 18 |

| Bulk Density(g/cm3) | 2.3 | 2.4 | 2.5 | 3.1 |

| Cold crushing strength(Mpa) | 13 | 14 | 32 | 36 |

| Thermal shock resistance (1100°Cwater cooling) cycle ≥ | 15 | 10 | 20 | 7 |

| Refractoriness(°C) | 1710 | 1750 | 1800 | 1800 |