We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

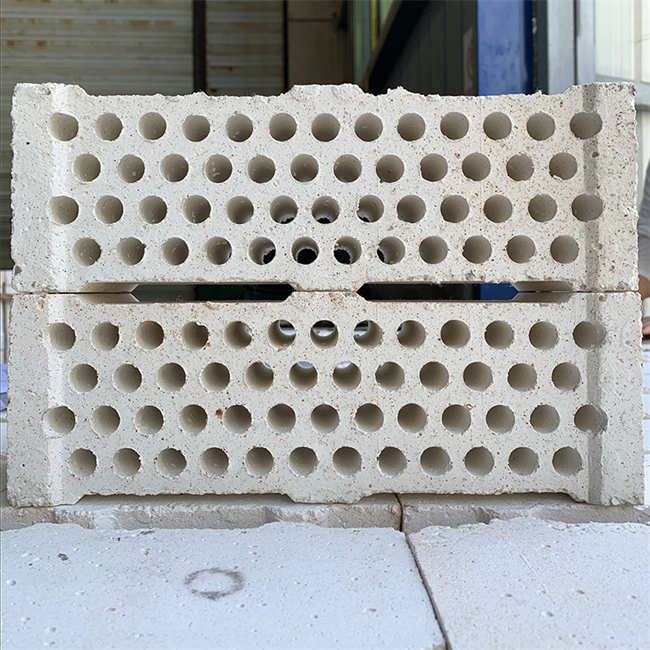

Brief introduction of fire block bricks

Fire block bricks are generally installed behind the burner of the regenerative furnace to support and reinforce the ceramic heat storage materials. It can also be used with honeycomb for various regenerative combustion systems. Features: good thermal shock stability, high softening point, strong chemical resistance, good thermal shock resistance.

Features of fire block bricks

Fire block brick can be used together with the honeycomb body for the front end of the regenerator of various regenerative combustion systems and hot chamber heaters. Its function is to protect the heat storage body and prolong its service life.

Fire block brick Fireproof bricks can be divided into corundum fused mullite baffle bricks, corundum synthetic mullite baffle bricks and sintered mullite baffle bricks according to their materials. They are formed by pouring, baking at high temperature and firing. Various sizes can be customized according to the drawing requirements.

Advantages of fire block bricks

Fire block brick is characterized by good thermal shock stability, high softening point, strong chemical resistance and good thermal shock resistance.

Parameters of fire block bricks

| Index | Type | DBZ-60 | DBZ-70 | DBZ-75 | DBZ-80 | DBZ-85 |

| – | Material | Alumina mulite | Alumina mulite | Alumina mulite | Capacitance corundum | Capacitance corundum |

| Chemical compstion(%) | AI2O3≥ | 60 | 70 | 75 | 80 | 85 |

| Bulk density(g/cm3) | 1500℃X3h≥ | 2.5 | 2.5 | 2.55 | 2.6 | 2.65 |

| Compsssion srength (MPa) | 1500℃X3h≥ | 70 | 80 | 90 | 100 | 110 |

| Modulus of rupture (MPa) | 1500℃X3h≥ | 8.0 | 8.5 | 9.5 | 11 | 12 |

| Permanent linear change(%) | 1500℃X3h | 0.6 | 0.5 | 10.4 | 士0.3 | 士0.2 |

| Max,service temperature ℃ | 1450 | 1550 | 1550 | 1600 | 1650 |