We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

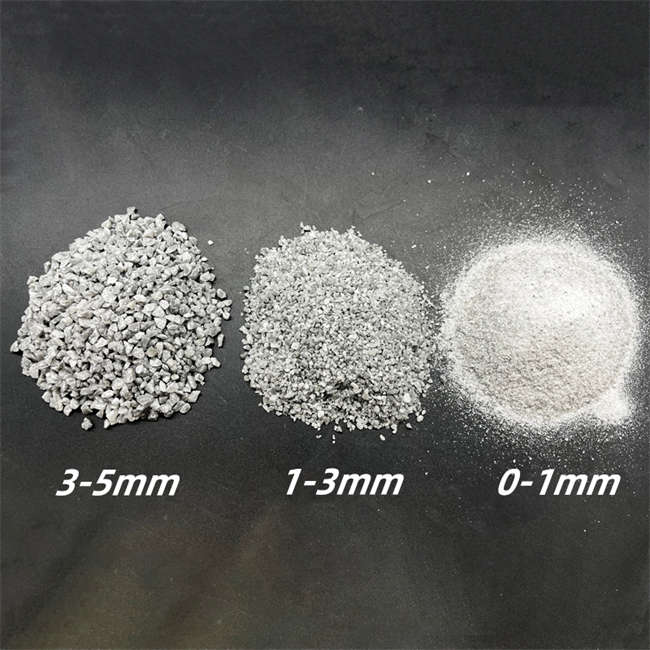

Product introduction of dense corundum

Dense corundum is a new type of high-purity refractory, which is made by melting high-purity alumina and reducing agent in a certain proportion in an electric arc furnace. The main crystalline phase of compact corundum is α- Al2O3, light gray in color, has high melting point, high bulk density and extremely low porosity, and has excellent wear resistance, slag resistance, volume stability and thermal shock resistance at high temperatures. It is the refractory material in the corundum series of refractory materials.

Description of dense fused corundum

Dense fused corundum is a kind of refractory material. Its main crystal phase is more than 96%, and its porosity is less than 4%. It has good acid resistance and alkali resistance. It has good wear resistance, corrosion resistance and volume stability at high temperature.

Technical Parameters of dense corundum

| Specification | Al2O3 | Fe2O3 | SiO2 | Na2O | Magnetic material % | |

| ǀ | Potential Sand | ≥98.3 | ≤0.15 | ≤1.0 | ≤0.1 | ≤0.05 |

| Fines | ≥97.8 | ≤0.3 | ≤1.0 | ≤0.1 | ≤0.1 | |

| ǁ | Potential Sand | ≥99.0 | ≤0.1 | ≤1.0 | ≤0.1 | ≤0.005 |

| Fines | ≥98.6 | ≤0.1 | ≤1.0 | ≤0.1 | ≤0.005 |

Application of dense corundum

Dense corundum is widely used in iron and steel metallurgy, petrochemical industry, building materials ceramics and other industries. It is mainly used as the refractory tamping material of the taphole of the blast furnace and the coagulant of the castable. It is also an excellent material for making long nozzles, slide plates and various corundum bricks.