We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

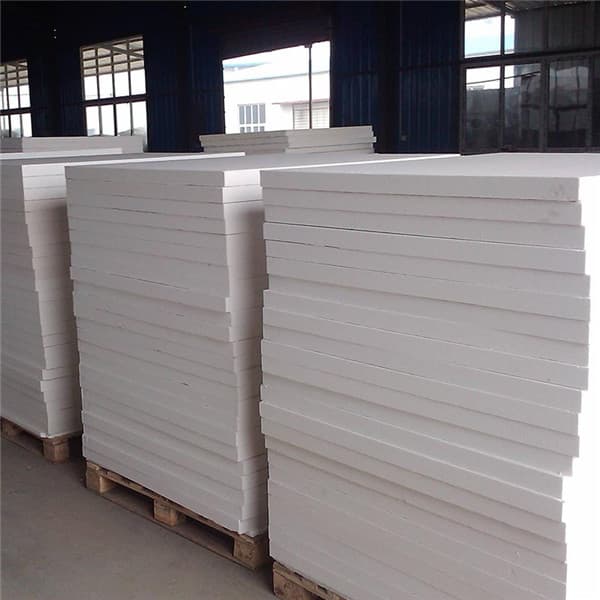

Product description of ceramic fiber board

In addition to the excellent performance of the corresponding ceramic fiber wool block, the ceramic fiber board also has a hard texture, excellent hardness and toughness, and excellent wind erosion resistance. It is an ideal material for energy conservation in ovens, pipes and other thermal insulation equipment, because it will not expand when heated, is light in weight, is easy to build, and can be cut and bent at will.

Features of ceramic fiber board

Excellent wind erosion resistance

Low heat, low thermal conductivity

The material is not brittle and has good toughness

Accurate size and good flatness

High compressive strength, long service life

Easy to cut and install, easy to construct

Continuous production, uniform fiber distribution, stable performance

Application of ceramic fiber board

- Heat treatment furnace back lining insulation

- Backup insulation in nonferrous metal industry

- Isolation of kiln bottom from cement and other building material industries

- Backup insulation of furnaces in petrochemical, metallurgical, ceramic and glass industries

Parameters of ceramic fiber board

| Type | Ordinary | Standard | High Purity | High Alumina | Zirconium |

| Classification temperature, ℃ | 1100 | 1260 | 1260 | 1360 | 1430 |

| Working temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Colour | white | Pure white | Pure white | Pure white | Pure white |

| B.D, kg/m3 | 260-320 | 260-320 | 260-320 | 260-320 | 260-320 |

| PERMANENT liner change, % 24Hours under ,B.D320kg/m3 | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| HEAT CONDUCTIVITY COEFFICIENT w/m·k | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) |

| B.D, 285kg/m3 | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) |

| B.D, 285kg/m3 | 0.180(1000℃) | 0.180(1000℃ ) | 0.180(1000℃) | 0.180(1000℃) | 0.180(1000℃) |

| STRENGTH EXTENSION, Mpa, THICKNESS SHRINKAGE 10% | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Al2O3 | 44% | 46% | 47~49% | 52~55% | 39~40% |

| Al2O3+SiO2 | 96% | 97% | 99% | 99% | – |

| Al2O3+SiO2+ZrO2 | – | – | – | – | 99% |

| ZrO2 | – | – | – | – | 15~17% |

| Fe2O3 | <1.2% | <1.0% | 0.2% | 0.2% | 0.2% |

| Na2O+K2O | ≤0.5% | ≤0.5% | 0.2% | 0.2% | 0.2% |